Filament Cutter

At Fillamentum, they know very well that if you try their material once, you won’t want another. Their filaments are simply addictive. However, you do not want to buy the entire spool immediately but try a sample to prove the quality at first. Therefore, the company asked us if we could help them to design a simple filament cutter to solve this issue.

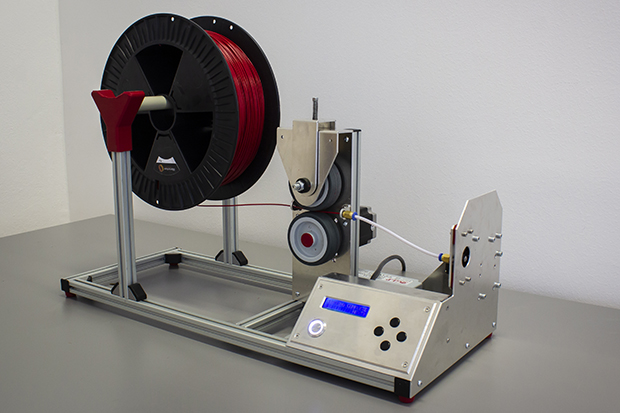

Production of samples worked for a long time manually. Unrolling a certain length from a large reel then cutting and wrapping it. Filament Cutter 1.0 aims to speed up and simplify this process. It is designed as a dedicated device where you set the length of the sample, their number and the machine will simply cut them.

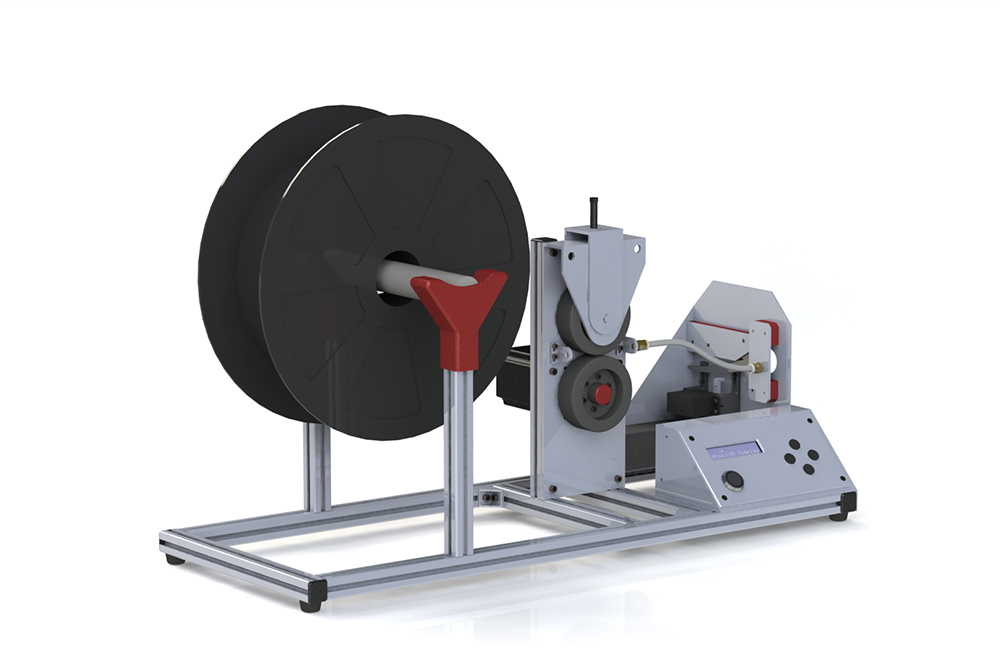

In the design, we focused on making the machine simple and reliable, minimizing material costs. The ideal construction solution was to use a standardized aluminum item profile combined with bent sheet metal parts and 3D printed plastic parts made of ASA. Taking into account only industrial beauty.

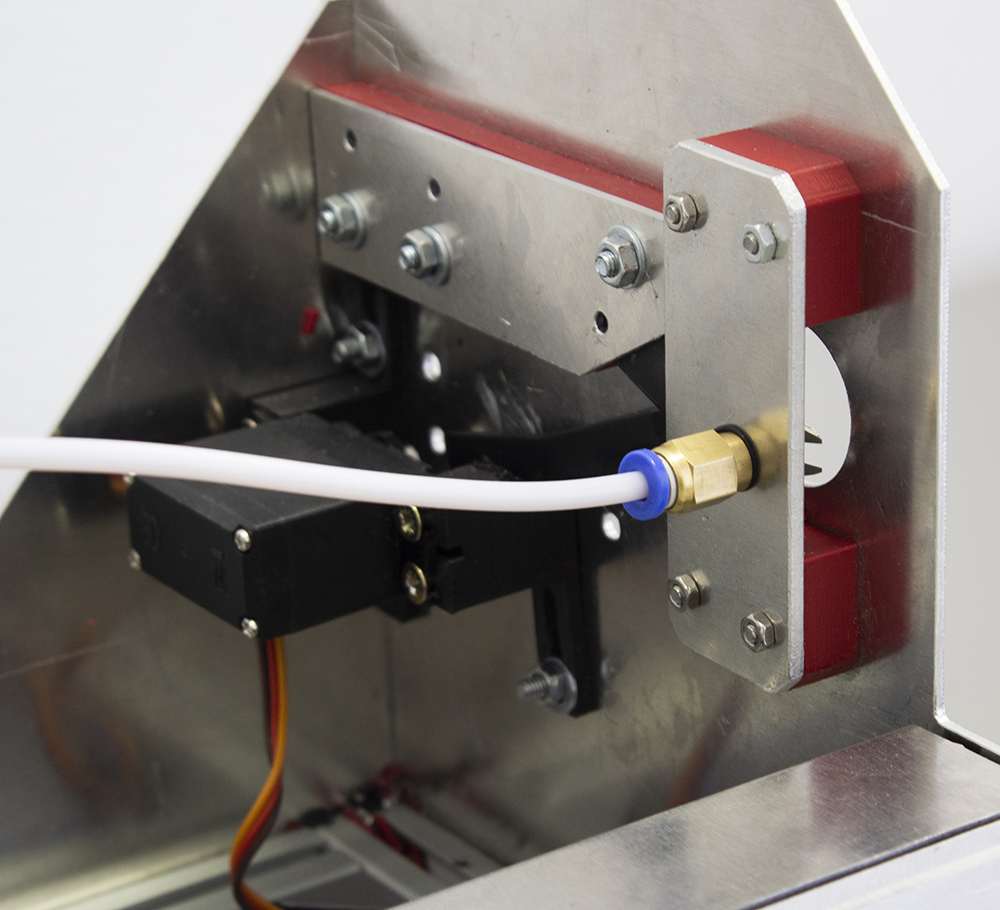

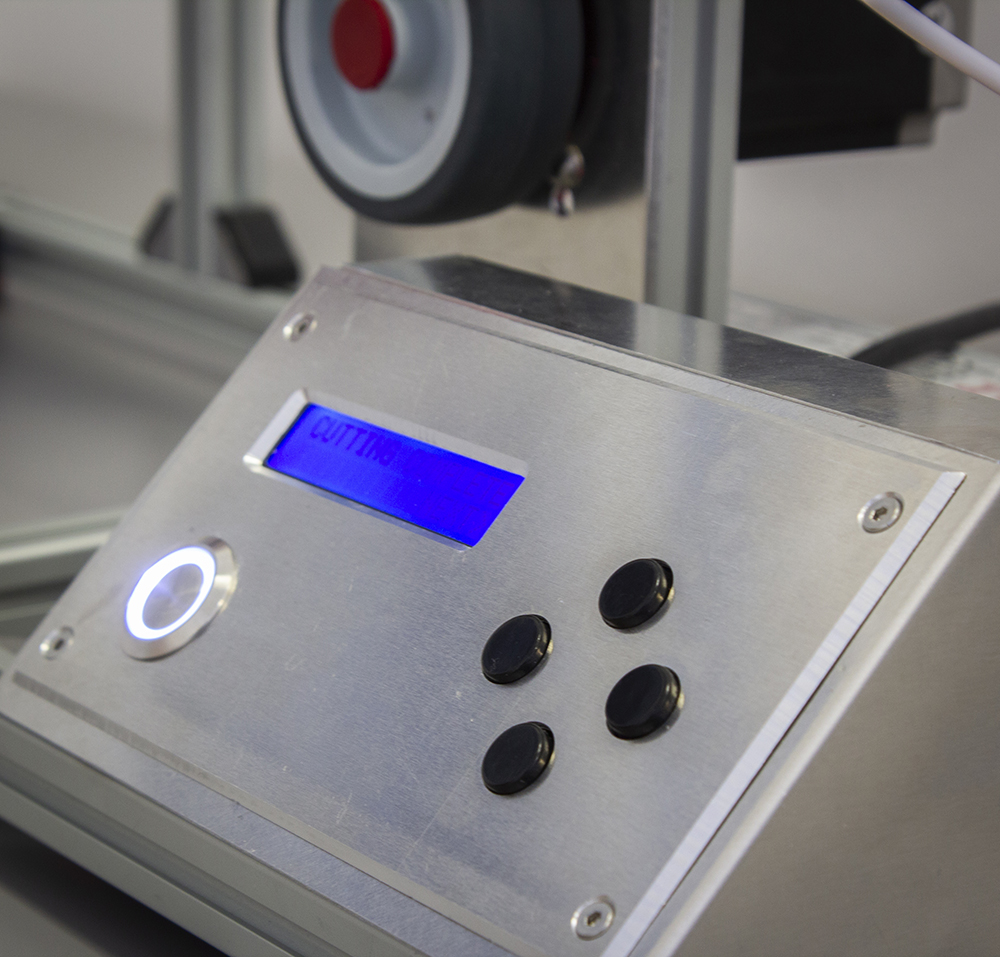

The electronic is built on microcontroller Atmega 328P which controls a servo motor and Nema 23 stepper motor. The second wheel is spring-loaded so the pressure can be adjusted. The movement of cutting shears is taken care of by a servomotor that has a metal gearbox. The user interface has a two-line LCD display and four operating buttons.

The device is currently being tested and should be able to produce 300 samples per hour (300 potential clients). We already know how to improve and automate version 2.0. However, we are pleased we could use all our main tools at the design process and prototyping – 3D printing, CNC machining, and reason.