Design and Prototyping

The foundation of the industry today is, without doubt, mass production. However, before the designed product or its part gets to the manufacturing stage and real life, it has to undergo several development phases. This is why the effectiveness and speed by which it undergoes these phases is an important factor in terms of success and competitiveness. The costs for prototyping need to be as low as possible and yet have to reliably test specific characteristics.

Advantages of 3D printing in design and prototyping

- Speed and accuracy – Getting feedback, either within the company or straight from the consumer in the shortest timeframe possible, is literally obligatory. However, you do not want this saved time to be used at the expense of quality. Quality handmade models can take several weeks, but with 3D printing you often gain quality in less time.

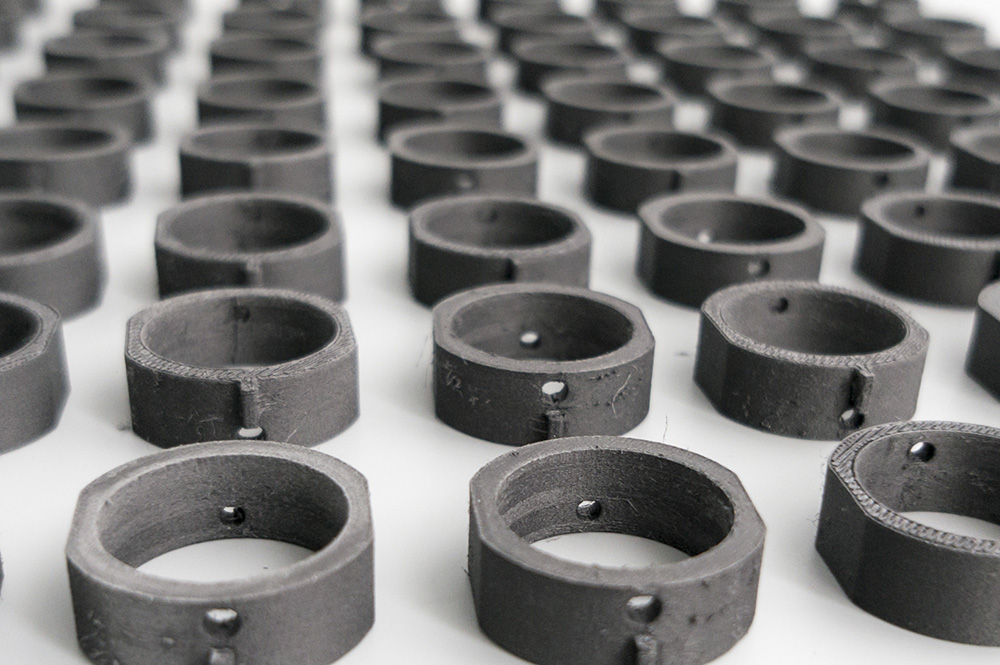

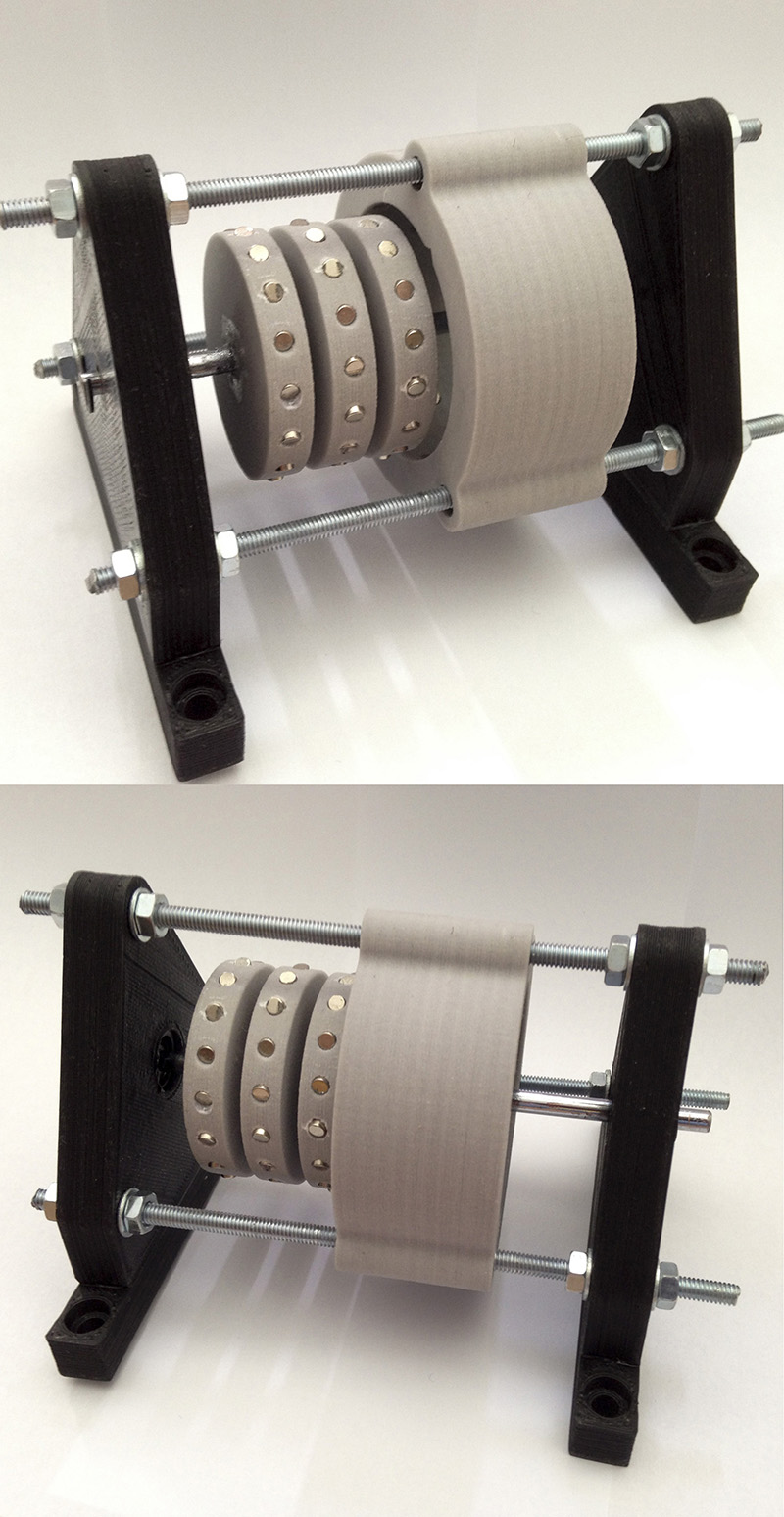

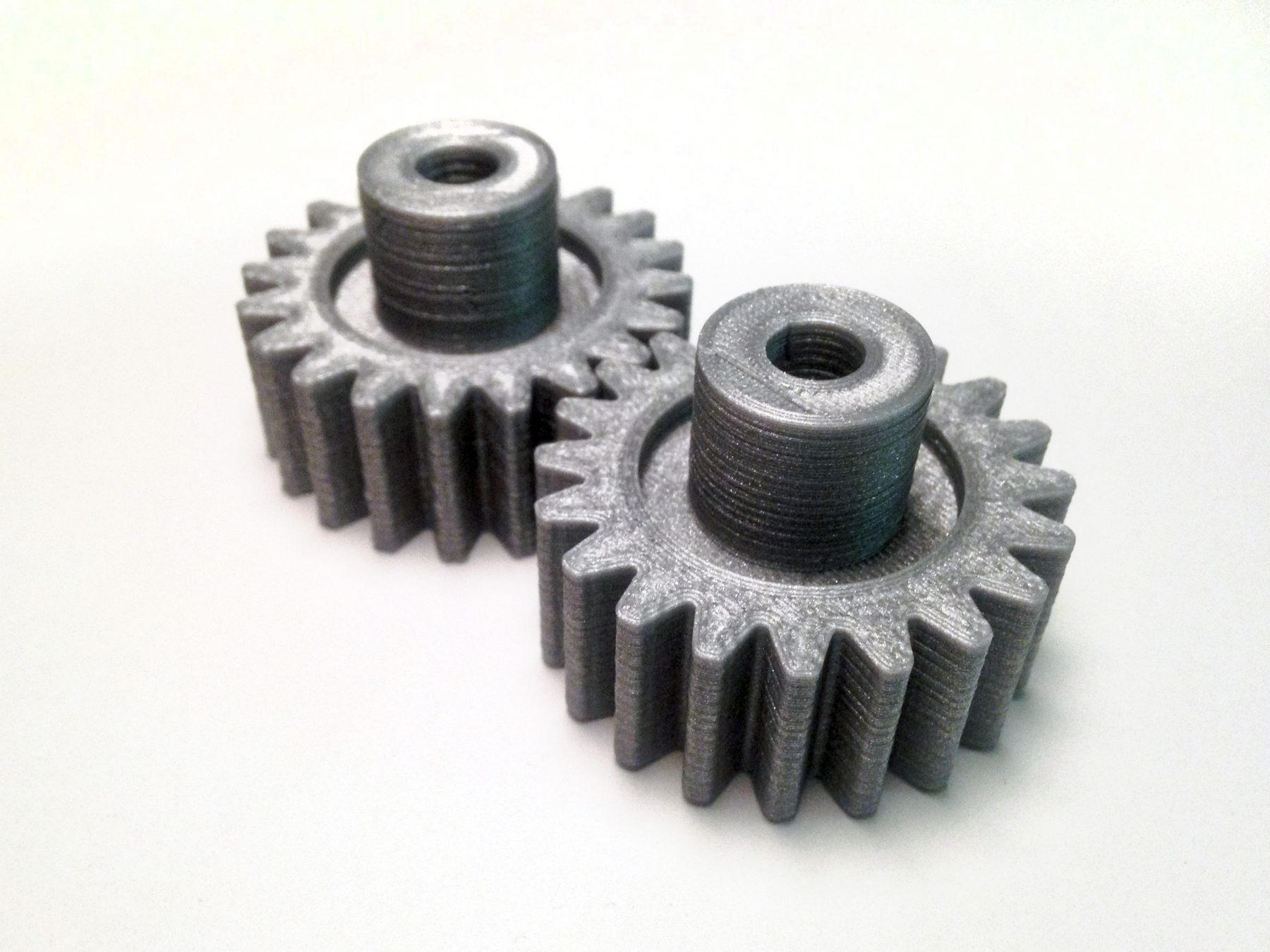

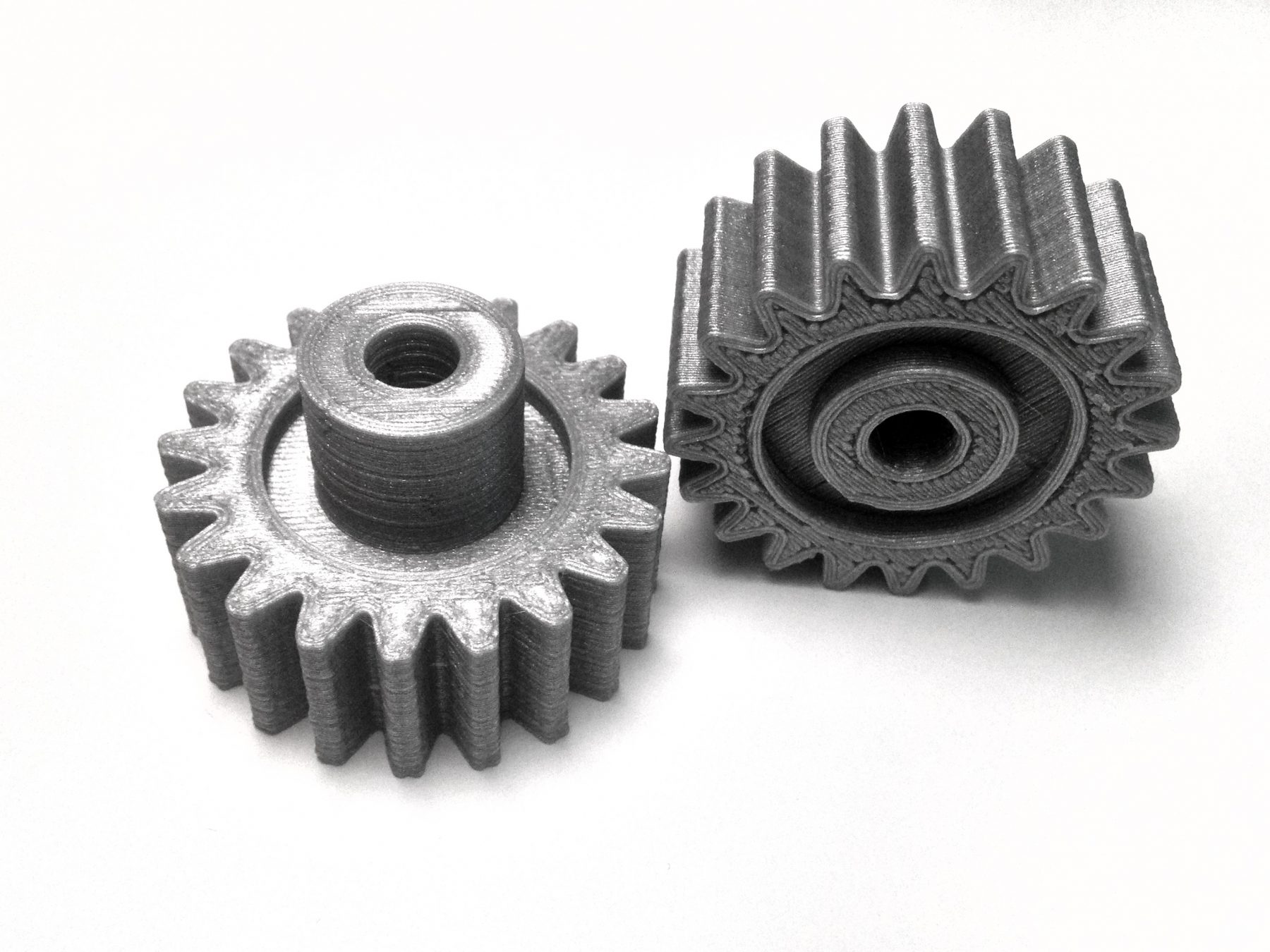

- Good material properties – If things other than shape design are involved, and you need to test mechanical characteristics of some parts or the stiffness of joints, 3D printing offers a range of materials thanks to which 3D printed objects can come close to or be as good as standard products.

- Complex shapes – Quality design requires thinking about the practicality of the product, and therefore the comfort of the user. Ergonomic shapes usually aren’t straight lines, but curves designed specifically to the human body. Making of these shapes is often more complicated and time-consuming. With 3D printing you gain shape freedom and you can focus on the comfort of users.

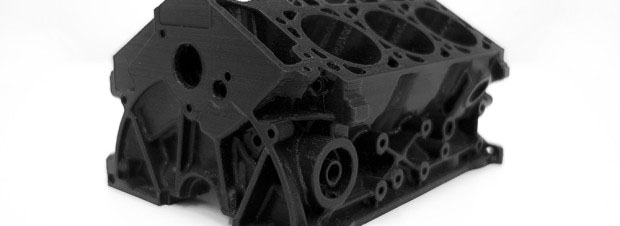

- Moulds production – With dimensionally complicated components the goal is to quickly and cost-effectively address mould production and master castings. 3D printing is used as an excellent complementary technology in this field.

Which technology is best?

According to our experiences, we recommend technology FFF (ABS, PLS plastics) for components and prototypes mechanically stressed; although there are some shape restrictions.

In the case of dimensional study and the aesthetic of design, we recommend inkjet powder (sandstone). Especially welcome in automobile industry and art design.

If you’re unsure which technology to use, contact us at info(at)tvaroch.sk and we’ll gladly help you.

Sportwatch – Rene Valenta, Stainless steel and Flexi material

Where next? How to print | Print a model