Flexible Material For You

We’re glad to finally include the flexible material we’ve been awaiting in our portfolio. It’s a material made by Formlabs that was introduced at the end of last year and recently it has arrived here. It’s a photo-polymeric resin made for the technology of SLA printers. We would categorize it as functional — to be used for the making and testing handles, seals or stamps. We tested it by making an iphone case.

Our experiance

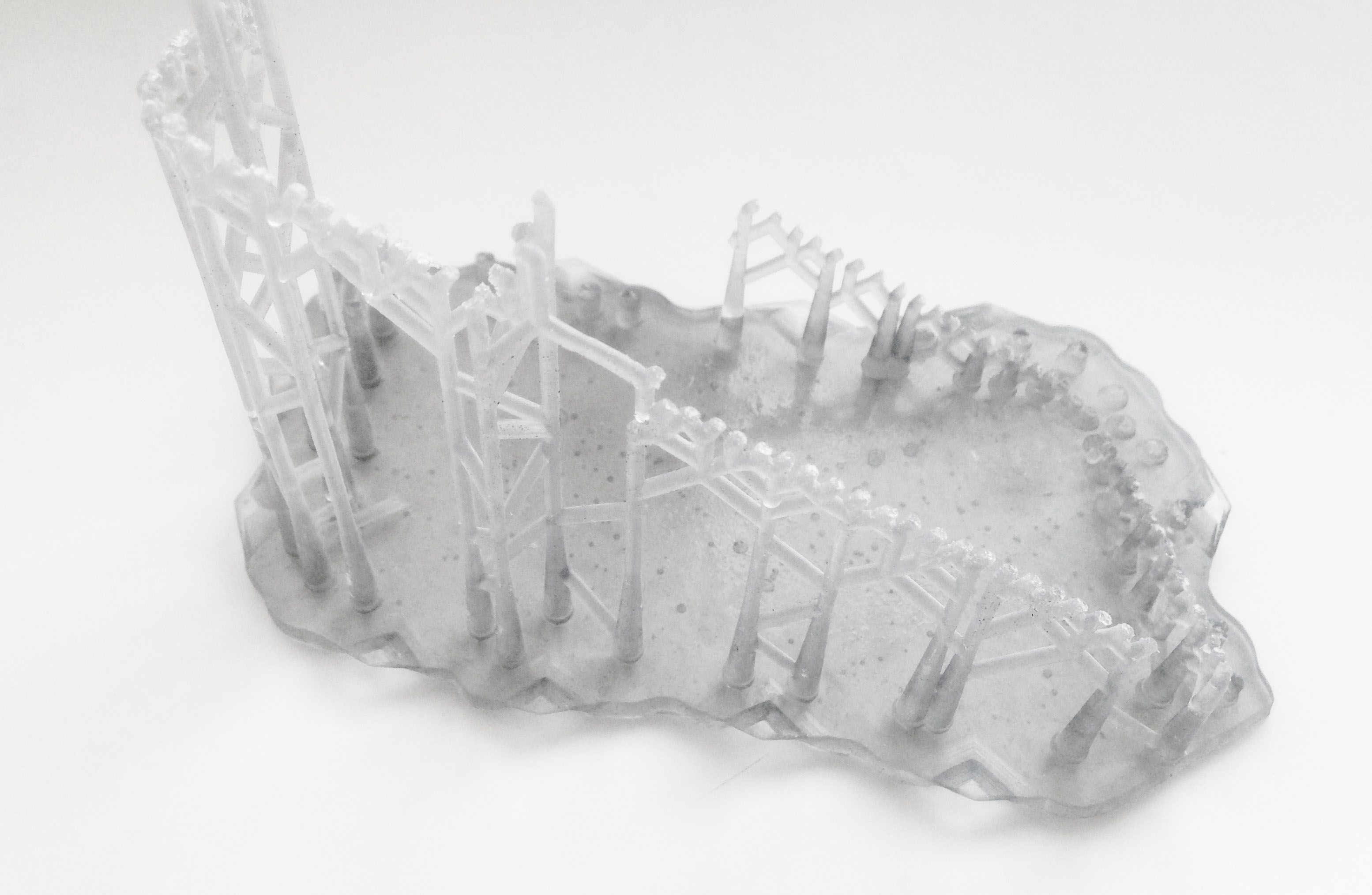

The material can be bought in ½ litre packs and is about a third more expensive than other resins. The rather denser consistency is an advantage in printing, since air bubbles are not formed. It’s see-through, with a blue tone. Because of its flexibility it’s near impossible to print thin parts, as we’re used with Formlabs.

A video posted by Tvaroch 3D Prototyping (@tvaroch3d) on

Bending the material isn’t a problem in all directions and even after multiple bends the structure didn’t break and no cracks appeared. The flexibility of the material is reduced and it doesn’t have the viscosity to drag it, as after a certain extension it begins to tear.

Generated supported structures are deeper and also its removal and smoothing is problematic. However, it’s possible to easily smooth the surface using sandpaper or a file — and likewise with solid materials.

Flexible material in our portfolio of materials.