Strength of ABS, detail of SLA

Nowadays, in terms of home printers there are two basic options. You either choose the path of resistant thermoplastics like ABS or PLA, which however don’t have a perfect surface and detail; or you choose good-looking prints from SLA or DLP printers and lower your demands on the qualities of the material. This problem was addressed in Formlabs by creating new photopolymer, which is as resistant as ABS but the printing preserves the detail of SLA printers. The new material was called Tough and this name should resemble its qualities. It was introduced at the end of June and it’s used mainly for engineer models requiring strength and resistance.

What is our experience?

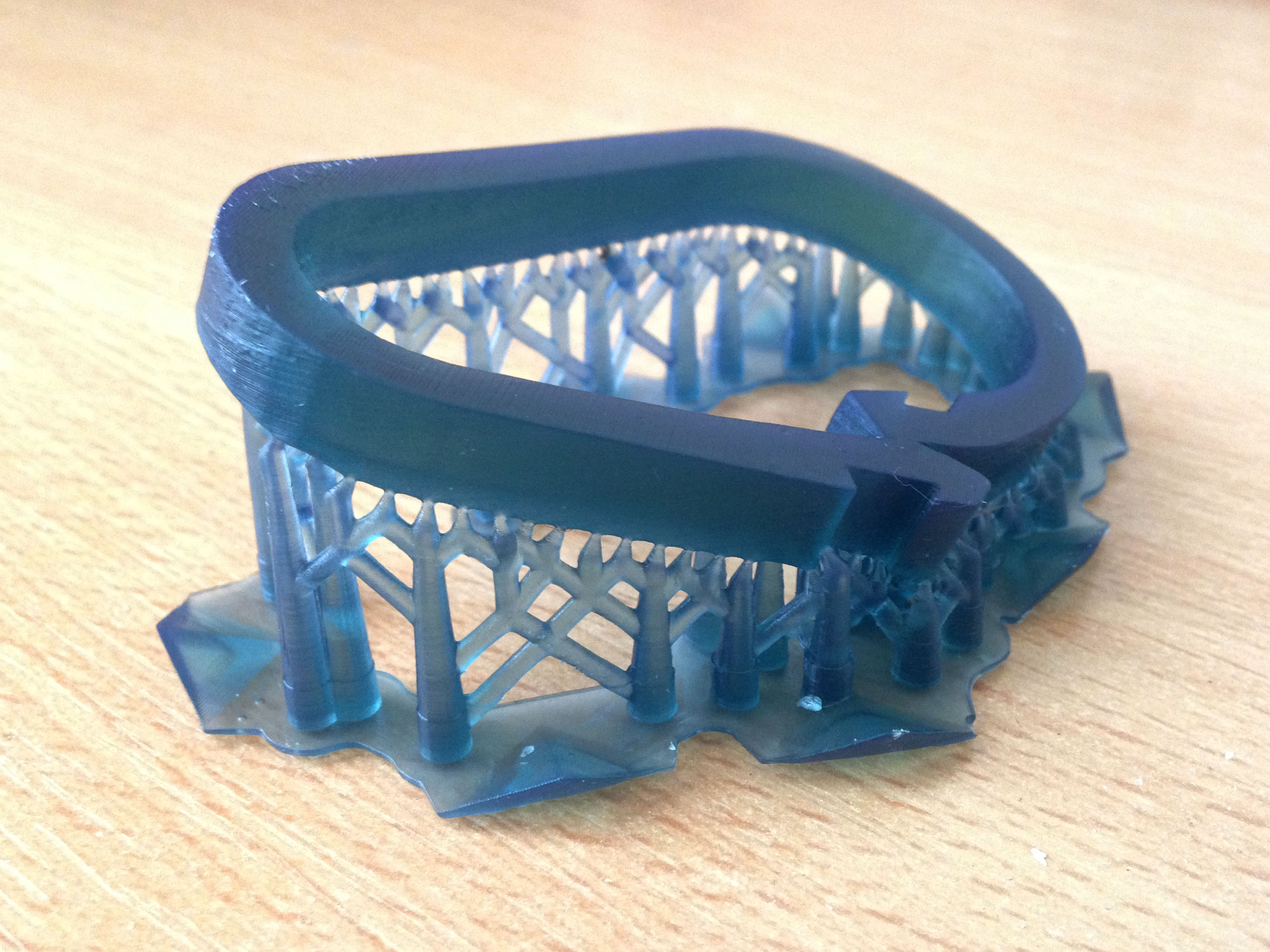

As the testing item we chose a carbine and our material sample “T”. For comparison we printed the same items from clear resin. The testing was mostly based on personal experience than exact measuring.

- When you were accustomed to technical material are mostly grey, white or black – Tough is made in translucent turquoise.

- While printing the carbine with generated supports from PreForm no problems appeared and the first print was successful. The T sample was printed worse. Even though the printing was successful and the surface was nice, the print was curled in some places. This problem was removed after adding some extra supports in the next print.

- Surface resistance was a bit of a disappointment, since it’s possible to dig into it with nails, similar as with standard resin.

- Compared to standard resin, it’s more flexible and less fragile. After bending, it slowly takes its original shape. Even after large deformation it gets into its original condition. Standard detailed resin loses most of its flexibility after one or two days in sunlight and it becomes solid and fragile. Solid tough resin kept its flexibility even after five days, therefore it is not expected this will change in time.

- The main quality of resistant detailed plast should be strength. This is why we decided to burden the printed carbines with bottles of our favourite drink Club Mate and test the strength in the pull. We began with a crate and four half-litre bottles of Mate. Gradually we added four bottles in the crate until we got to 28 bottles (approximately 17 kg). After getting to 17 kg the carbine made of ordinary detailed plast broke. Tough resin endured and there was only partial elastic deformation. Given the great flexibility of tough resin, we could have added many more bottles.

Summary

Our first experience and testing show, that a new material can withstand a lot but its flexibility can be a disadvantage in certain applications. However, we gained overview to be able to recommend to our clients the correct application.

Technical parameters of Tough resin

Materials and Technologies – Detailed plastic resistant