Elastic resin

The most elastic available 3D printed material with elongation up to 160% and hardness only 50A shore. Material is suitable for functional products, where simulating flexible characteristics of rubber or silicone is necessary.

Typical use

Models and products with flexible parts. Typically, soft silicone and urethane parts for applications like wearables, medical models, robotics.

Also see Applying 3D printing

Design guide

Maximum size1: 145 x 145 x 175 mm

Minimal wall thickness: 0,6 mm

Minimum details2: 0,1 mm

Layer height: 0,1 mm

1 largest model size printed as one piece, larger models are required to be printed as separate parts but they can easily be connected

2 details and structures of models smaller than the minimum details size can be wrongly portrayed or get lost entirely

material properties (datasheet)

Finishing

The final model can be edited further to achieve even smoother surface.

Colouring is suitable when the base is basic paint for plastic surfaces and afterwards acrylic spray paint.

For bonding, epoxy glue, which creates flexible joint, has proven effective.

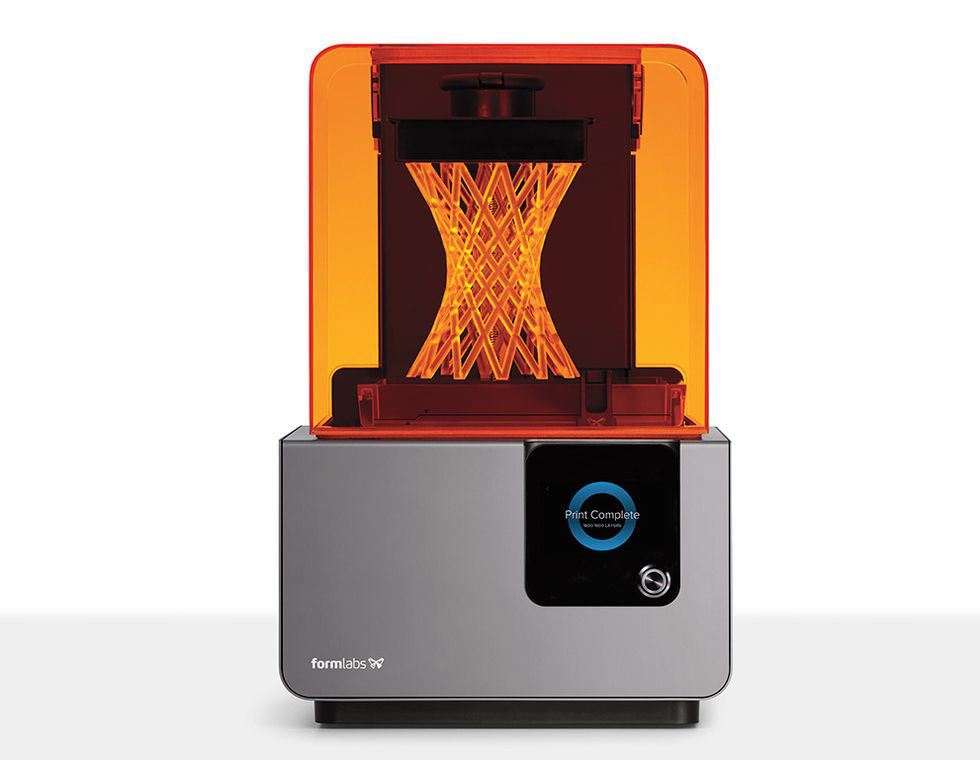

Technology

Layering acrylic based photopolymer cured with UV light by the company Formlabs. It creates smooth surface and accurate geometry.

Printer, Form 2

Ships in

1 – 3 business days

Properties

Resistance ***

Surface roughness *****

Details ****

Flexibility *****

Transparency ****

+ PROS

resistance

high level of detail

accuracy

– CONS

limited range of colors