What is 3D printing

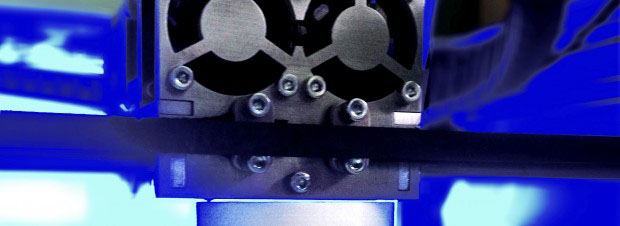

3D printing is an additive manufacturing process of making three dimensional solid objects from a digital file (3D model). Objects are created by laying down successive layers of material.

Layered materials can be plastics, resins, metals or even ceramic composites. One of the oldest methods of 3D printing – stereolithography – was already developed in the middle of the 1980s.

Developing of 3D printing

Alike most new technologies, 3D printing was for a long time only an area for specialists. The potential of this technology was recognised and it slowly found its way into new branches. In the beginning, these branches were mostly research centers such asaeronautics and space industries, where innovation is necessary and innovation is a question of survival. Next in line were the mechanical engineering and automobile industries. In Formula 1 it enabled quick testing of new models of monoposts, which was a great improvement and an advantage for constructors.

With the falling price of 3D printers, the popularity of 3D printing rose. Designers and architects also quickly understood the advantages of this technology. They could easily and quickly test new solutions for their designs. Instead of months or weeks, they had a functioning model in a few hours. It drastically reduced costs and enabled the development of new products and their prototyping. Today it’s also used for production of a small series of products and it can replace traditional fabrication in the future.

For a long time, the problem of greater popularization of 3D printing was the price of printers. Larger companies protected their patents and slowed down the development of this technology. An important step in history was to make technology FDM (Fused Deposition Modeling) accessible. Objects are created by extruding melted material. The most common molten material is ABS or PLA. The most of home/hobby 3D printers are based on this technology.

Much credit goes to Adrian Bowyer, who started project RepRap. It’s an open-source self-replicating 3D printer. From parts worth approximately €300, practically anyone who has any technical knowledge and skills can make their own 3D printer. The exactly equivalent term, fused filament fabrication (FFF), was coined by the members of the RepRap project to give a phrase that would be legally unconstrained in its use.

The next natural step will be the spreading of 3D printers to homes, alike inkjet and later laser printers, have been spread to homes and offices. Today, experts give the invention of the 3D printer the same kind of prospects as the invention of the Internet. Just like you can print any text or picture, in the world of 3D printing you will have the ability to print real objects.

Our goal is to effectively support the spread of this technology and access to it. For news on this, check out our pinterest, twitter or linkedin.

Applications of 3D printing

Today this technology is still in its infancy and the possibilities of usage are adding up — every day better and better new printers are being deveploped and new materials used for printing are being invented. Currently there are more than a hundred, many types of plastic, porcelain, glass, precious metals or composites, which simulate wood. Depending on the technology used and material it’s possible to please many diverse needs and requirements of specific branches.

Where to go? Make model | 3D model